|

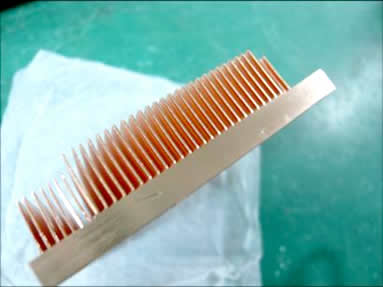

Skived Fin Process

Another very efficient fin manufacturing method is the skived fin where we take a piece of material, slide thin fins and bend them to stand up at 90 degrees with one end still connected to the material. This eliminated the soldering process and make the fin work very efficient. We use a CNC machine to produce the fins in copper and aluminum and the cost is fairly low.

For skived fin the minimum fin to fin space can be 1.0mm and minimum fin thickness can be 0.35mm

Skived Fin Process

Skived Fin Process

|