Mold design software:

Pro/E, Solid work ,UG,

Master Cam, AutoCAD, etc.

Mold manufacturing equipments:

CNC machine, EDM,

wire cutting machine,

mold fitting machine, etc.

Mold base material:

LKM Standard Mold Base

Mold insert material:

SE-8407, DE-2344, JP-SKD61,

USA-H13, etc.

We also have all above material made in China.

CN-8407, CN-H13,CN-2344,

CN-SKD61, etc.

Mold life:

Aluminum Die Casting Mold: 40000~80000 shots

Zinc Die Casting Mold: 200000~400000 shots

Mold lead time: 30 ~40 days

Technical Parameter:

1.The minimum wall thickness we can make:

Aluminum alloy parts: 1.0mm;

Zinc alloy parts: 0.8mm;

2.Minimum surface roughness : Ra 1.6 ;

3.Maxinum casting area: 700 cm2 ;(for DCC280)

4.Maxinum casting weight: 2.9Kg ; (for DCC280)

5.Minimum tolerance: CT4 .

Form and position tolerance:±0.1mm;

Hole tolerance:±0.025mm;

|

Molding shop

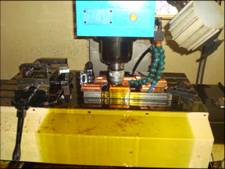

CNC machine

Our Mould

Mold fitting machine

Mold warehouse

|